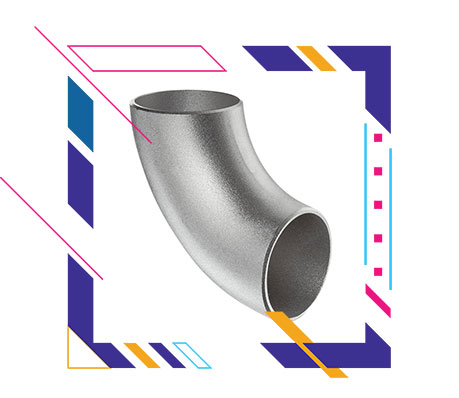

WP9 Alloy Steel Buttweld Fittings, Alloy Steel A234 WP9 Elbow, WP9 CrMo LR Elbow, Ready Stock Of Gr WP9 Alloy Steel Pipe Fittings, Manufacturer of ASTM A234 CrMo WP9 Pipe Elbow Supplier in Mumbai.

Unifit Metal Alloys is an acknowledged trader and supplier of AS A234 WP9 Pipe Fittings, which are available to our esteemed customers at market-leading rates.

We have been able to supply our valued clients with a wide variety of this Alloy Steel ASTM A234 WP9 Butt Weld Reducer Pipe Fittings due to our years of industrial expertise, which is made by the entity's experts using cutting-edge equipment. We provide a high grade superior quality variety of this alloy that is made with high quality raw materials and sophisticated technology designed by our experts. With the constant emphasis on the ongoing market trends, we put forth a distinct variety of these products, which are manufactured as per industry norms and praised for their durability and fine finish.

CrMo WP9 Buttweld Fittings, Gr WP9 Alloy Steel Pipe Fittings, Alloy Steel WP9 90 Degree Elbow, WP9 Alloy Steel Pipe Cap, ANSI B16.9 WP9 CrMo Welded Fittings, Alloy Steel A234 WP9 Short Radius Elbow, WP9 Alloy Steel Reducer, Cr-Mo A234 WP9 Stub End Manufacturer In Mumbai, India.

As an approved dealer, distributor, and seller in the industry, we are engaged in presenting a wide variety of this ASTM A234 Alloy Steel WP9 Butt Weld Cross Pipe Fittings, which is widely desired in the market for its characteristics such as no durability in nature. We provide these products at reasonable rates to meet the requirements of our business customers. Furthermore, we provide these products in a variety of sizes, shapes, and diameters to suit the needs of our customers. In the pursuit of becoming the finest brand in the industry, we are involved in providing these products, which are highly valued in the industry for their thermal resistance. The quality-tested product is made accessible to meet the various needs of the clients.

Our business is well-known for providing customers with this ASME SA 234 Alloy Steel WP9 Butt Weld Stub Ends Pipe Fittings, which is primarily used to improve strength, hardness, and chemical resistance. Our logistics team ensures that the consignments of this alloy are shipped on time to the clients' locations using simple dispatch methods. Furthermore, before final dispatch, we test these products on a variety of factors to ensure that they are in accordance with worldwide quality standards. It has characteristics such as durability, high tensile strength, and corrosion resistance, pipe covering protection, chemical resistance, and easy adjustment.

Get a best quote for Alloy Steel A234 WP9 Seamless Fittings, We Keep Bulk Stock of Cr-Mo A234 WP9 Buttweld Pipe Fittings at our stockyard, contact us to request a quote.

Alloy Steel A234 WP9 Pipe Fittings Specifications

| Specifications | ASTM A234 / ASME SA234 |

|---|---|

| Dimensions | ASME/ANSI B16.9, ASME B16.28, MSS-SP-43, BS4504, BS4504, BS1560, BS10 ASME 16.11, MSS SP-79, 83, 95, 97, BS 3799 |

| Size | Seamless Fittings: 1/2" - 10" Welded Fittings: 1/2" - 48" |

| Thickness | SCH10, SCH20, SCH30, STD SCH40, SCH60, XS, SCH 80, SCH 100, SCH 120, SCH 140, SCH 160, XXS available with NACE MR 01-75 |

| Manufacturing Standards | ASME/ANSI B16.9, ASME B16.28, MSS-SP-43 DIN : DIN2605, DIN2615, DIN2616, DIN2617, DIN28011, DN15-DN1200 BS : BS4504, BS4504, BS1560, BS10 JIS : JIS B2311, JIS B2312, JIS B2313, JIS B2316 GOST : GOST 17375, GOST 17376, GOST 30753, GOST 17378, GOST 17379, GOST 17380 EN: EN10253-1, EN10253-2 |

| Types | Seamless / ERW / Welded / Fabricated |

| Connection | Welding |

| Bending Radius | R=1D, 2D, 3D, 5D, 6D, 8D, 10D or Custom |

| Elbow | Angle : 22.5 deg, 30deg, 45 deg, 90 deg, 180 deg, 1.0D, 1.5D, 2.0D, 2.5D, 3D, 4D, 5D, 6D, 7D-40D. Standard: ASME B16.9, ASME B16.28, ASME B16.25, MSS SP-75 DIN2605 JISB2311 JISB2312 JISB2313, BS, GB, ISO |

| Manufacturing process | Push, Press, Forge, Cast, etc. |

| Specialized manufacturer of | 90º Elbows, Couplings, Reducers, Inserts, Caps, Nipples, 45º Elbows, Tees, Crosses, Equal Tees & Reducing Tees |

| Test Certificates | EN 10204/3.1B Raw Materials Certificate 100% Radiography Test Report Third Party Inspection Report, etc |

| Material Test Certificates (MTC) as per EN 10204 3.1 and EN 10204 3.2, Test Certificates certifying NACE MR0103, NACE MR0175 | |