Grade P12 Cr-Mo Pipes & Tubes, P12 Alloy Steel Seamless Tubes, Ready Stock Of CrMo P12 Tubing, Manufacturer of ASTM A335 Alloy Steel P12 Welded Tube, Alloy Steel A335 P12 Pipes Supplier in Mumbai.

Unifit Metal Alloys is a well-known exporter and trader of AS ASTM A335 P12 Pipes & Tubes, which are well-known for their toughness, well-built, durability, and dependability.

Alloy Steel ASME SA 335 P12 EFW Pipes are also extremely immune to chloride assault, including pitting/crevice corrosion and stress corrosion cracking. In all circumstances, it is non-magnetic and has good weldability and formability. The addition of copper to these products improves their resilience to powerful reducing acids, especially sulphuric acid. It does contain significant amounts of the expensive elements nickel and molybdenum. They have reduced melting temps and have been used since the dawn of time. Because this product can now satisfy many of the uses in which this grade previously worked well at a reduced cost, it is used less frequently than in the past.

Grade P12 Welded Pipes, Chrome-Moly P12 ERW Pipes, ANSI B16.9 Alloy Steel A335 P12 Heat Ex-changer Tubes, Grade P12 Cr-Mo Seamless Pipes, Alloy Steel ASTM A335 P12 Butt Weld Fittings, A335 Grade Cr-Mo P12 Bush Hex Pipe, Alloy Steel P12 90 Square Pipe, P12 Alloy Steel Electropolish Pipe Manufacturer In Mumbai, India.

Similar but not necessarily exact characteristics of these ASTM A335 Alloy Steel P12 ERW Pipes are defined in the specifications of other products. They are generally not appropriate for use at temps above 300 degrees Celsius. The lesser thermal expansion coefficient of these products when compared to austenitic types lowers distortion and related stresses. This steel's high strength, which makes it useful in a variety of uses, also lowers its machinability, but it still machines slightly better than other alloys. This steel's austenitic composition provides it exceptional toughness, even at cryogenic temps.

The great strength of these ASME SA 335 Alloy Steel P12 Hexagonal Tubes also makes bending and forming more challenging, where this alloy is heated to 1020° C - 1080° C and quickly cooled. This alloy's operations will necessitate bigger capacity equipment than would be needed for an austenitic structure. Because the ductility of this material is lower than that of an austenitic grade (but not lower than that of most other structural materials), harsh forming operations, such as cold heading, are usually not feasible. It is suggested that interim annealing be performed if extreme cold working is needed. They have a diverse set of useful characteristics, and iron-bearing rock is plentiful. Copper compounds have been used since prehistoric times.

Get a best quote for Alloy Steel ASTM A335 P12 Pipes & Tubes, We Keep Bulk Stock of Alloy Steel P12 Seamless Bare Pipe at our stockyard, contact us to request a quote.

AS ASTM A335 P12 Pipes & Tubes Specifications

| AS P12 Pipes & Tubes Specifications | ASTM A335, A249, A269, A358 / ASME SA335, SA249, SA269, SA358 |

|---|---|

| Dimensional specification | ANSI/ASME B36.19M, ANSI/ASME B36.10M |

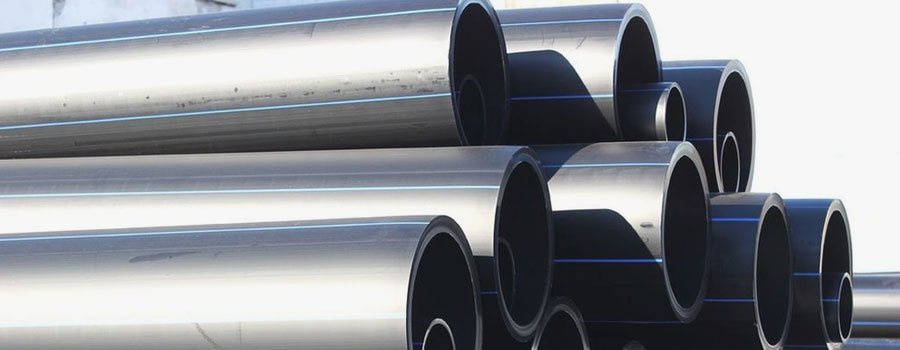

| ASTM A335 TP AS P12 Seamless Pipe & Tube Size | 1 / 2" NB - 16" NB |

| ASTM A335 TP AS P12 Welded Pipe & Tube Size | 1 / 2" NB - 24" NB |

| ASTM A358 TP AS P12 EFW Pipe & Tube Size | 6" NB - 24" NB |

| Outside Diameter | 6.00 mm OD up to 914.4 mm OD, Sizes up to 24” NB available Ex-stock, OD Size Steel Tubes available Ex-stock |

| AS P12 Pipes & Tubes Manufacturing Shapes | Hydraulic, Round, Rectangle, Square, Hex, Honed |

| AS P12 Pipe & Tube Manufacturing Techniques | Seamless / Welded / ERW / Fabricated / CDW / 100% X Ray Welded |

| Alloy Steel P12 Pipe & Tube Schedule Thickness Range | SCH 5, SCH10, SCH 40, SCH 80, SCH 80S, SCH 160, SCH XXS, SCH XS |

| AS P12 Pipes & Tubes End Types | Plain End, Beveled End, Treaded One End, TBE (Treaded Both Ends) |

| Delivery Condition of AS P12 Pipe & Tube | Annealed and Pickled, Polished, Bright Annealed, Cold Drawn |

| Surface Finish | No.1, No.4, No.8 Mirror Finish, 2B |

| Value Added Services | Cutting, Beveling, Polishing, Threading, Destructive, Non Destructive, Ultrasonic Testing |

| Inspection and Test Reports | EN 10204 3.1, Mill Test Certificates, Chemical Reports, PMI Test Reports, Mechanical Reports, Third Party Inspection, NABL Approved Lab, Visual Inspection, Destructive Test and Non Destructive Test Reports |

| Marking | Specification Grade Nominal Pipe Sizes Pipe Schedule or Wall Thickness Manufacturing Method (Seamless / Welded) Heat Number Manufacturer’s Name or Custom Logo - on request Marked Pipe Sample: ANSI B36.19 ASTM A 312 TP 304 12" NB SCH 40S SEAMLESS HEAT NO. XXXX |

| Outside Finish | 2B, No.4, No.1, No.8 Mirror Finish for Alloy Steel Pipes, Finish as per customer Requirements |

| Delivery Condition | Annealed and Pickled, Polished, Bright Annealed, Cold Drawn |

| Packing of AS P12 Pipes & Tubes | Packed in Wooden Boxes, Plastic Bags, Steel Strips Bundled, or as per Customers Requests |

| Specials | Sizes and Specifications other than above can be on request |