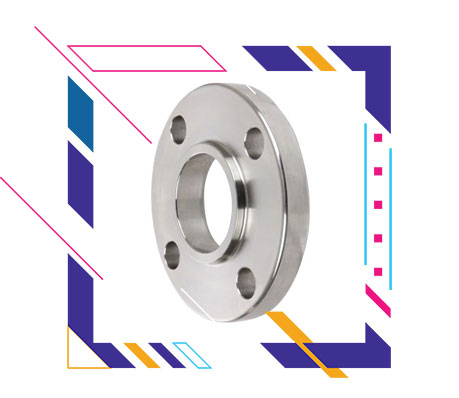

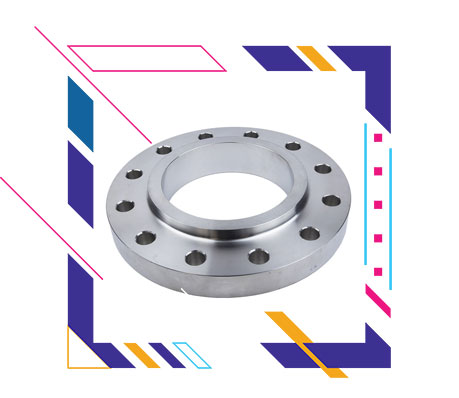

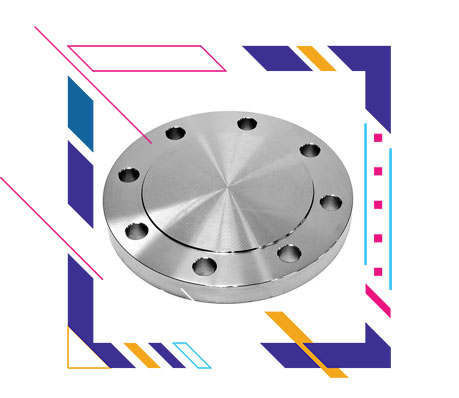

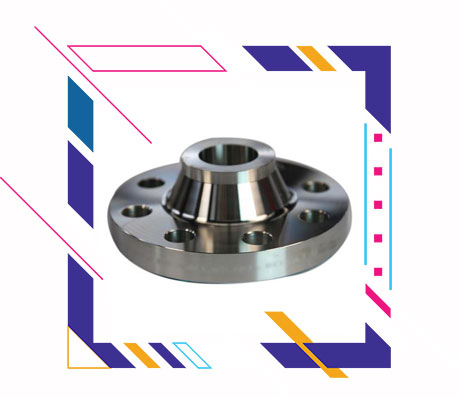

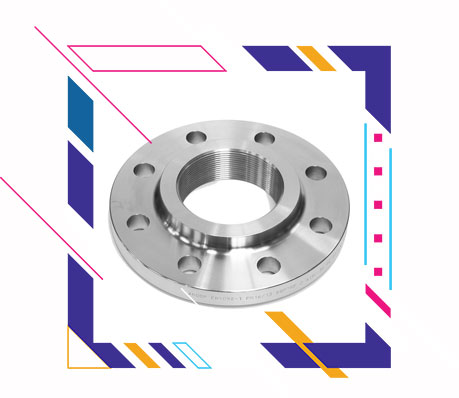

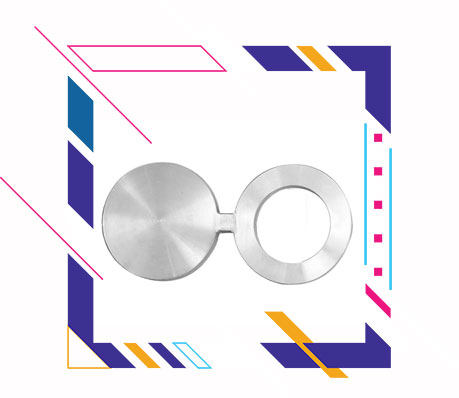

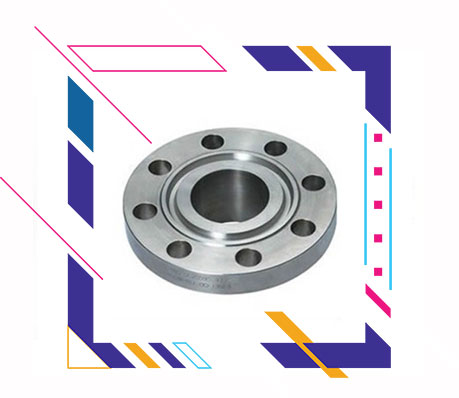

Alloy C22 SORF Flanges, C22 Hastelloy Long Weld Neck Flanges, Ready Stock Of Nickel Alloy C22 Flanges, Manufacturer of ASTM B564 Hastelloy C22 Lap Joint Flanges, Hastelloy Alloy C22 Threaded Flanges Supplier in Mumbai.

Unifit Metal Alloys is a supplier of Hastelloy Alloy C22 Flanges, which is more resistant to intergranular corrosion. Hastelloy UNS N06022 Slip On Flanges is a columbium-containing stabilised austenitic chromium nickel steel that eliminates carbide precipitation and, as a result, inter-granular corrosion. It is frequently utilised as a stabilised alternative when columbium is employed as the stabilising agent. Because of its low tantalum and cobalt content, it should be evaluated for nuclear applications.Collector rings, annealing box covers, aviation exhaust heaps, jet engine parts, tubing, fasteners, flexible metal bellows and hose, expansion joints, and other applications call for it. These are iron-based alloys with at least 10.5 percent chromium content.

UNS N06022 Blind Flanges, Hastelloy C22 Square Flange, Alloy C22 Slip On Flange, Hastelloy® Alloy C22 Lap Joint Flanges, ANSI B16.5 Hastelloy C22 RTJ Flanges, DIN 2.4602 Socket Weld Flanges, C22 Hastelloy Flanges, Hastelloy Alloy C22 WNRF Flange Manufacturer In Mumbai, India.

Hastelloy WNR 2.4602 Weld Neck Flanges are stabilised steels that have a good resistance to inter-granular corrosion after being exposed to temperatures in the chromium carbide precipitation range of 800 to 1500 degrees Fahrenheit (427 Degree C to 816 Degree C). It employs columbium as a stabilising ingredient to enhance its main characteristic: resistance to inter-granular corrosion. It is used for building elements that must be resistant to scaling up to 1050 degrees Celsius. In highly oxidising settings, it offers somewhat better corrosion resistance than other steels. It is a chromium nickel austenitic steel with niobium stabilisation and corrosion resistance comparable to other steels.It improves the current ability to endure intergranular corrosion for maximal capabilities.

Nickel Alloy C22 Blind Flanges is commonly employed at temperatures ranging from 800 to 1500 degrees Fahrenheit, where it is stabilised against chromium carbide precipitation by the accumulation of niobium, resulting in the precipitation of niobium carbides. Because of its outstanding mechanical qualities, it is also appropriate for high temperature service. It's resistant to air corrosion, sterilising solutions, a wide range of organic compounds, and a wide range of inorganic chemicals. It is austenitic steel that has been stabilised with columbium and tantalum, similar to other steels. They obtain their stainless properties by forming an undetectable and sticky Chromium rich oxide coating.The inclusion of titanium prevents the development of chromium carbide.

Get a best quote for Hastelloy C22 SORF Flanges, We Keep Bulk Stock of Hastelloy Alloy C22 Flanges at our stockyard, contact us to request a quote.

Hastelloy C22 Flanges Specifications

| Size Chart | 1/2" (15 NB) to 48" (1200NB) DN10~DN5000 |

|---|---|

| Standards | ANSI/ASME B16.5, B16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, GOST Flange, ASME/ANSI B16.5/16.36/16.47A/16.47B, MSS S44, ISO70051, JISB2220, BS1560-3.1, API7S-15, API7S-43, API605, EN1092 |

| Pressure Rating | Class 150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS |

| Pressure Calculation in DIN | 6Bar 10Bar 16Bar 25Bar 40Bar / PN6 PN10 PN16 PN25 PN40, PN64 |

| UNI | 6Bar 10Bar 16Bar 25Bar 40Bar |

| EN | 6Bar 10Bar 16Bar 25Bar 40Bar |

| Coating | Oil Black Paint, Anti-rust Paint, Zinc Plated, Yellow Transparent, Cold and Hot Dip Galvanized |

| Most common types | Forged / Threaded / Screwed / Plate |

| Test Certificates | EN 10204/3.1B Raw Materials Certificate 100% Radiography Test Report Third Party Inspection Report, etc |

| Production Technique | Forged, Heat treated and machined |

| Connect Type/ Flange Face Type | Raised Face (RF), Ring Type Joint (RTJ), Flat Face (FF), Large Male-Female (LMF), Lap-Joint Face (LJF), Small Male-Female (SMF), Small Tongue, Large Tongue & Groove, Groove |

| Special design | As per your drawing AS, ANSI, BS, DIN and JIS |

| Test | Direct-reading Spectrograph, Hydrostatic testing machine, X-ray detector, UI trasonic flaw detector, Magnetic particle detector |

| Equipment | Press machine, Bending machine, Pushing Machine, electric bevelling machine, Sand-blasting machine etc |

| Manufacturer of | ANSI DIN, GOST, JIS, UNI, BS, AS2129, AWWA, EN, SABS, NFE etc. B.S: BS4504 , BS3293, BS1560, BS10 The other standard: AWWA C207; EN1092-1, GOST12820, JIS B2220; KS B1503, SABS1123; NFE29203; UNI2276 |