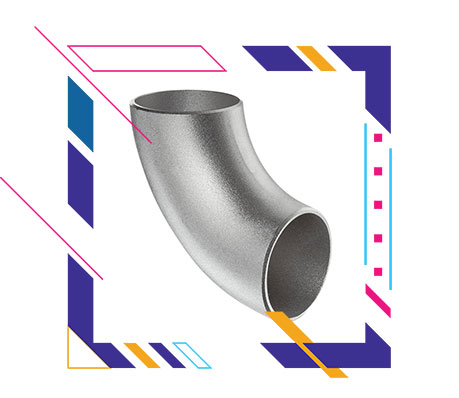

Ready Stock Of SS 904L Pipe Fittings, Manufacturer of ASTM A403 904L Pipe Elbow, Stainless Steel 904L Buttweld Fittings, SS 904L Elbow, 904L SS LR Elbow Supplier in Mumbai.

Unifit Metal Alloys is a known trader and stockist of SS 904L Pipe Fittings, which is made of high-quality metal and is completely strong and rust-proof in construction.

Stainless Steel UNS N08904 Elbow Pipe Fittings comes in a variety of sizes that are determined by their interior and exterior diameters. It is a type of gasket designed to fit between two flared-up sections of pipe to increase surface area. They are utilised for joints in the petroleum and chemical industries. It has a nut on the head and is a threaded rod with two hefty hexagon nuts. Meanwhile, this alloy in inches corresponds to the effective thread length that is measured similarly to the league, from the first to the first thread devoid of points.

DIN 1.4539 Stub End, Stainless Steel 904L Short Radius Elbow, UNS N08904 Buttweld Fittings, ANSI B16.9 Stainless Steel 904L Welded Fittings, 904L Stainless Steel Pipe Fittings, SS 904L Reducer, SS 904L Pipe Cap, SS 904L 90 Degree Elbow Manufacturer In Mumbai, India.

But, in Stainless Steel WNR 1.4539 Buttweld Tee Pipe Fittings product, the first thread is defined as the junction of the major length of the thread via the pedestal of the point. It has a plate with a data tap and a pair of flanges with included taps. This steel is used to provide access to a line for measuring liquids or gases. It is intended to be used in conjunction with a set of gaskets, bolts and nuts, and a jackscrew to aid in splitting the flanges for orifice testing. It has a gasket appearance in the same plane as the bolting circular surface. It also has an inside component that is the same size as the pipe and an exterior ring with bolt holes.

Never the less, these Alloy 904L Buttweld Reducer Pipe Fittings should not be used in areas where there is constant bending pressure. We provide fine category of alloy that is essentially in ring or disc form and is attached to a pipe to provide better strength and support. They are often screwed or welded to the pipe end and linked with fasteners. In addition, the gasket in this product is inserted between the mating flanges to achieve a tighter seal. This alloy is frequently used in functions where the fitting or mating is manufactured from a casting.

Get a best quote for SS WP904L Seamless Fittings, We Keep Bulk Stock of Stainless Steel 904L Buttweld Pipe Fittings at our stockyard, contact us to request a quote.

Stainless Steel 904L Pipe Fittings Specifications

| Specifications | ASTM A403 / ASME SA403 |

|---|---|

| Dimensions | ASME/ANSI B16.9, ASME B16.28, MSS-SP-43, BS4504, BS4504, BS1560, BS10 ASME 16.11, MSS SP-79, 83, 95, 97, BS 3799 |

| Size | Seamless Fittings: 1/2" - 10" Welded Fittings: 1/2" - 48" |

| Thickness | SCH10, SCH20, SCH30, STD SCH40, SCH60, XS, SCH 80, SCH 100, SCH 120, SCH 140, SCH 160, XXS available with NACE MR 01-75 |

| Manufacturing Standards | ASME/ANSI B16.9, ASME B16.28, MSS-SP-43 DIN : DIN2605, DIN2615, DIN2616, DIN2617, DIN28011, DN15-DN1200 BS : BS4504, BS4504, BS1560, BS10 JIS : JIS B2311, JIS B2312, JIS B2313, JIS B2316 GOST : GOST 17375, GOST 17376, GOST 30753, GOST 17378, GOST 17379, GOST 17380 EN: EN10253-1, EN10253-2 |

| Types | Seamless / ERW / Welded / Fabricated |

| Connection | Welding |

| Bending Radius | R=1D, 2D, 3D, 5D, 6D, 8D, 10D or Custom |

| Elbow | Angle : 22.5 deg, 30deg, 45 deg, 90 deg, 180 deg, 1.0D, 1.5D, 2.0D, 2.5D, 3D, 4D, 5D, 6D, 7D-40D. Standard: ASME B16.9, ASME B16.28, ASME B16.25, MSS SP-75 DIN2605 JISB2311 JISB2312 JISB2313, BS, GB, ISO |

| Manufacturing process | Push, Press, Forge, Cast, etc. |

| Specialized manufacturer of | 90º Elbows, Couplings, Reducers, Inserts, Caps, Nipples, 45º Elbows, Tees, Crosses, Equal Tees & Reducing Tees |

| Test Certificates | EN 10204/3.1B Raw Materials Certificate 100% Radiography Test Report Third Party Inspection Report, etc |

| Material Test Certificates (MTC) as per EN 10204 3.1 and EN 10204 3.2, Test Certificates certifying NACE MR0103, NACE MR0175 | |