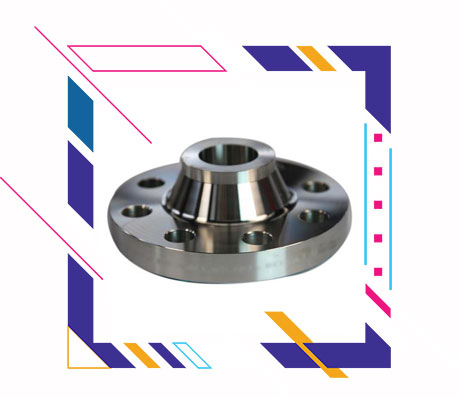

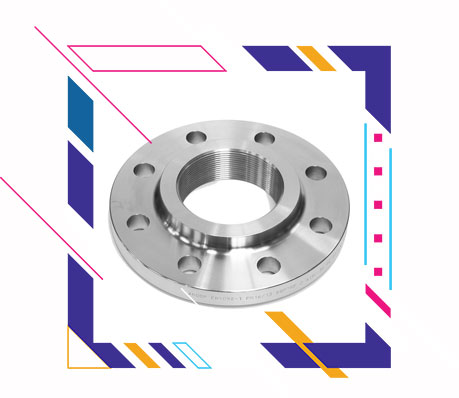

Duplex Steel S31803 SORF Flanges, Ready Stock Of Duplex S31803 Flanges, Manufacturer of ASTM A182 S31803 Lap Joint Flanges, S32205 DSS Long Weld Neck Flanges, DSS S32205 Threaded Flanges Supplier in Mumbai.

Unifit Metal Alloys is a supplier of Duplex Steel Pipe Flanges, whichhave excellent low temperature resilience and are non-magnetic when annealed.

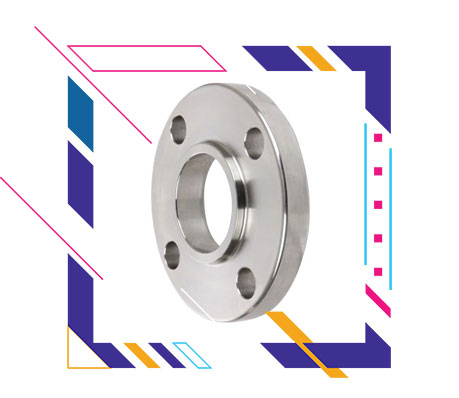

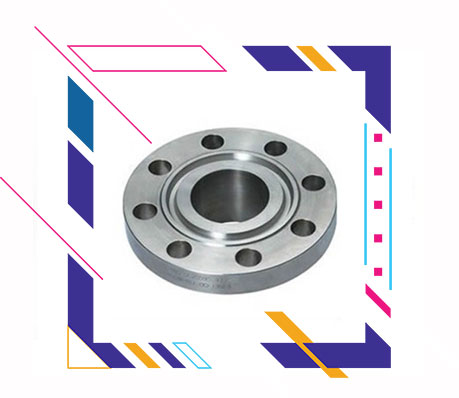

Duplex Steel S31803 Slip On Flanges are resistant to polyphonic acid stress corrosion cracking, which is common in oil plants. After exposure to this temperature range, it has good intergranular corrosion resistance, and this grade defies oxidation up to 1500 Degree F and has increased creep and stress rupture characteristics. To regain optimal corrosion resistance, they must be water quenched or completely annealed after working. It is unresponsive to thermal treatment, whereas cold working can improve the hardness and weight of the steel. It is stabilised with columbium, or sometimes tantalum, in addition to its greater carbon concentration. In most cases, the carbon level allows for dual accreditation.

Duplex Steel UNS S32205 Long Weld Neck Flanges, Duplex Stainless Steel S31803 SORF Flanges, Manufacturer of ASTM A182 S31803 Lap Joint Flanges, Ready Stock Of Duplex S32205 Flanges, DSS S31803 Threaded Flanges Manufacturer In Mumbai, India.

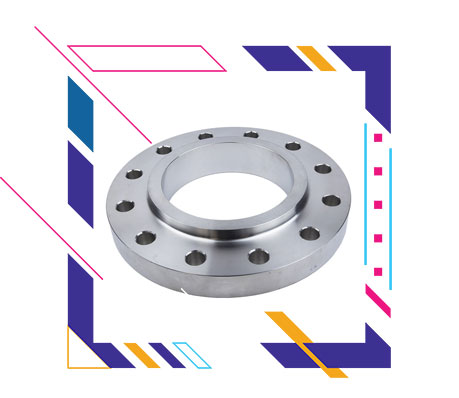

Duplex Steel S32205 Weld Neck Flanges is a stabilised variant designed to aid in intergranular corrosion protection. Collector rings, aircraft exhaust stacks, annealing box covers, jet engine components, expansion joints, tubing, fasteners, pliable metal pipe, and bellows are all common applications for this steel.In the annealed state, it is basically non-magnetic and can only be toughened by cold working. Instead of titanium, this product uses niobium to stabilise the carbon, which has better corrosion resistance and enables this grade to be used in operation at much higher temps close to 1500 degrees Fahrenheit. The columbium is used to create a stable version that is resistant to chromium carbide deposition.

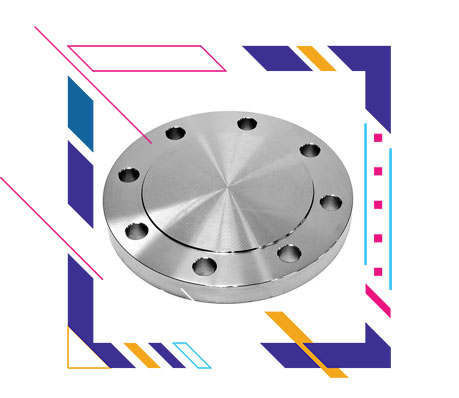

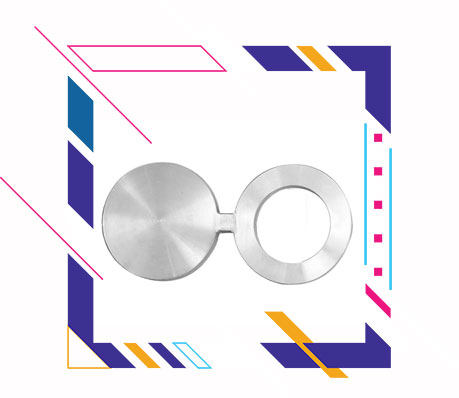

The primary benefit of these Duplex Alloy 2205 Blind Flanges is its exceptional resilience to intergranular corrosion, which occurs in other austenitic steels after contact to temps ranging from 800 Degree F to 1500 Degree F. And so this product has good creep strength up to 1500 Degree F, good corrosion resistance in applications, and good resistance to intergranular rust as bonded. Although this product necessitates greater starting pressures, it is robust and ductile, and it can be easily stamped, blanked, spun, and drawn. Long-term heating in the chromium carbide precipitation region may impact the product's overall resilience in highly corrosive media.

Get a best quote for DSS S31803 SORF Flanges, We Keep Bulk Stock of Duplex Steel S32205 Flanges at our stockyard, contact us to request a quote.

Duplex Steel S31803/S32205 Flanges Specifications

| Size Chart | 1/2" (15 NB) to 48" (1200NB) DN10~DN5000 |

|---|---|

| Standards | ANSI/ASME B16.5, B16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, GOST Flange, ASME/ANSI B16.5/16.36/16.47A/16.47B, MSS S44, ISO70051, JISB2220, BS1560-3.1, API7S-15, API7S-43, API605, EN1092 |

| Pressure Rating | Class 150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS |

| Pressure Calculation in DIN | 6Bar 10Bar 16Bar 25Bar 40Bar / PN6 PN10 PN16 PN25 PN40, PN64 |

| UNI | 6Bar 10Bar 16Bar 25Bar 40Bar |

| EN | 6Bar 10Bar 16Bar 25Bar 40Bar |

| Coating | Oil Black Paint, Anti-rust Paint, Zinc Plated, Yellow Transparent, Cold and Hot Dip Galvanized |

| Most common types | Forged / Threaded / Screwed / Plate |

| Test Certificates | EN 10204/3.1B Raw Materials Certificate 100% Radiography Test Report Third Party Inspection Report, etc |

| Production Technique | Forged, Heat treated and machined |

| Connect Type/ Flange Face Type | Raised Face (RF), Ring Type Joint (RTJ), Flat Face (FF), Large Male-Female (LMF), Lap-Joint Face (LJF), Small Male-Female (SMF), Small Tongue, Large Tongue & Groove, Groove |

| Special design | As per your drawing AS, ANSI, BS, DIN and JIS |

| Test | Direct-reading Spectrograph, Hydrostatic testing machine, X-ray detector, UI trasonic flaw detector, Magnetic particle detector |

| Equipment | Press machine, Bending machine, Pushing Machine, electric bevelling machine, Sand-blasting machine etc |

| Manufacturer of | ANSI DIN, GOST, JIS, UNI, BS, AS2129, AWWA, EN, SABS, NFE etc. B.S: BS4504 , BS3293, BS1560, BS10 The other standard: AWWA C207; EN1092-1, GOST12820, JIS B2220; KS B1503, SABS1123; NFE29203; UNI2276 |