API 5CT Grade L80 Super 13 Casing Pipe, API 5CT OCTG Tubing Supplier in Mumbai.

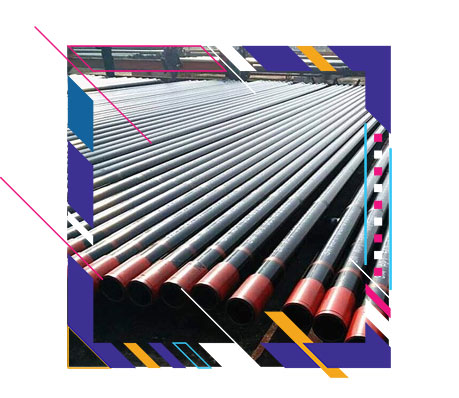

The low carbon content preserves the martensitic microstructure while enhancing weldability. Its primary use is in the OCTG tubing & casing and down hole completion equipment, and it is available in bar or tube form. When the extensive range of sizes available can be compared to the bill of materials needs, significant production and raw material supply cost savings can be made in comparison to the same bar product. Purchase API 5CT GR. L80 Super 13 Carbon Steel Piping from us for a fair price.

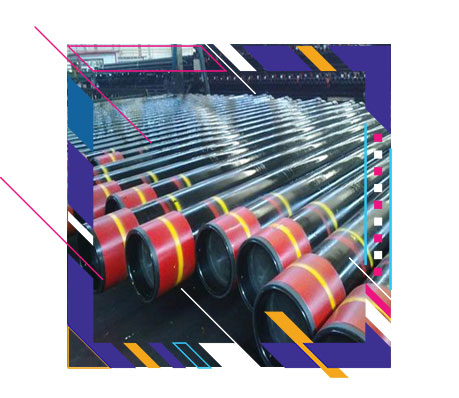

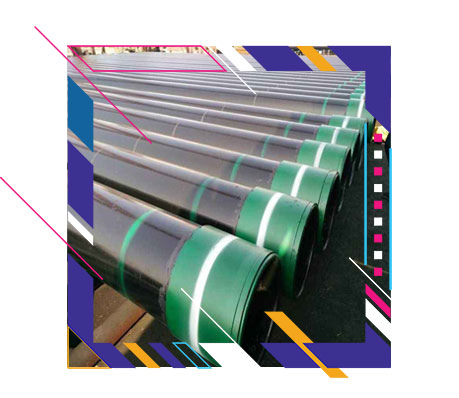

API 5CT PIPE, L80 Super 13 API OIL CASING PIPE, API 5CT GR. L80 Super 13 SEAMLESS LINE PIPE, API 5CT CASING PIPE, GRADE L80 Super 13 API 5CT LINE PIPES, CARBON STEEL GR. L80 Super 13 API 5CT TUBING, GR. L80 Super 13 API 5CT SEAMLESS PIPES, COLD ROLLED CARBON STEEL API 5CT PIPE AND TUBE Manufacturer In Mumbai, India.

Carbon Steel API 5CT Grade L80 Line Tubing is made using premium materials and cutting-edge technology under the direction of competent personnel. Super 13 API 5CT GR. L80 Carbon steel pipes are frequently used in the maritime and petrochemical industries, among many others. These pipes are often used to deliver fluids inside the well as well as oil and gas from the wellhead to the surface. Steel pipes, such as API 5CT L80, are crucial parts of the oil and gas sector because they ensure the effectiveness and safety of operations.

Get a best quote for API 5CT GRADE L80 Super 13 Carbon Steel Pipes, We Keep Bulk Stock of API 5CT L80 Super 13 Carbon Steel Pipes at our stockyard, contact us to request a quote.

API 5CT L80 Super 13 Pipe Specifications

| Material | L80 Super 13, steel grade |

| Specification | API 5CT/ISO 11960 |

| Wall Thickness | 1.0milimeter – 30 milimeter |

| Outer Dia | 4 1/2 Inch-20 Inch, (114.3-508milimeter) |

| Tubing Dimensions | 26.7 milimeter (1.05 Inch) to 114.3 milimeter (4.5 Inch) |

| Casing Dimensions | 114.3 milimeter (4.5 Inch) to 406.4 milimeter (16 Inch) |

| Length | maximum 12000 milimeter |

| Thread type | LC(Long round thread), SC(Short round thread), BC(Buttress thread) |

| API 5L | API 5L GR.46 / 42 / 52 / 60 / 56 / 65 / 80/ 70 |