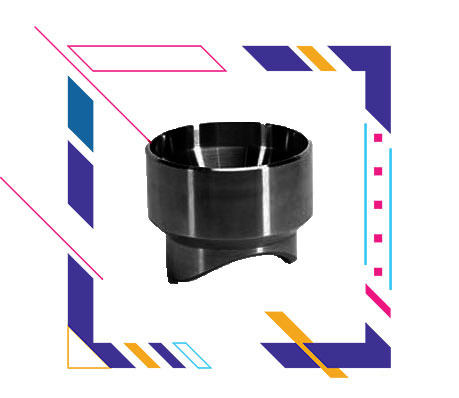

Alloy Steel A182 Outlet, Manufacturer of ASTM A182 AS F9 Flexolet, Alloy Steel F9 Flexible Outlet, Ready Stock Of AS F9 Threadolet, F9 Alloy Steel Threading Outlet Supplier in Mumbai.

Unifit Metal Alloys is an acknowledged stockist and seller of AS ASTM A182 F9 Outlets, which are available in a variety of quality-oriented characteristics.

Alloy Steel ASME SA 182 F9 Elbolet are made by rolling metal and welding the seam together. We are busy with offering a wide range of this steel that is used for moving liquid pours. This alloy's specification includes electrical-fusion-welded steel tubing for high-pressure operation at moderate temperatures. This steel's standard includes electric-fusion-welded steel tubing with filler metal added, made from pressure vessel grade plate in a variety of analyses and strength levels. We sell and make high-quality products that are used for transmitting high pressures of liquid substances and are available in a variety of specifications.

Cr-Mo A182 F9 Outlet, ANSI B16.9 Alloy Garde F9 Flexible Outlet, F9 Alloy Steel Sockolet, CrMo F9 Nippolet, Chrome Moly F9 Socket weld Outle, Alloy Steel A182 Swagged Nippolet, Alloy Steel ASTM A182 Gr. F9 Welding Outlet, Alloy Steel Grade F9 Latrolet Tee Manufacturer In Mumbai, India.

ASTM A182 Alloy Steel F9 Sock Outlets have great tensile strength, strong performance, corrosion abrasion resistance, and a variety of coatings. We offer a distinguished variety of these products, which are made from premium grade raw materials and work admirably. We have been providing high quality of these products using the most advanced technology and the most dependable quality. They are used in a variety of sectors for a variety of uses such as flare stacks, FEED for heaters, hydrocracking, and so on. They are used in process plumbing, power plant piping, refineries, LNG ports, natural gas storage, and other uses.

ASME SA 182 Alloy Steel F9 Weld Outlets are also used in heat exchangers, high pressure uses, welded pressure containers for cryogen storage, and other similar applications. It has some great characteristics, such as uniform thickness, longer service life, corrosion, chemical and thermal protection, and so on. They are typically manufactured from a solid round metal billet that has been heated and pressed or dragged over a form until it has been formed into a hollow tube. They are simple to install, long-lasting, and strong enough to withstand high pressure. These products have a number of exceptional characteristics such as rust resistance, durability, robustness, non-corrosiveness, and so on. They are suitable for high-pressure operation at ambient and lower temps.

Get a best quote for Alloy Steel F9 Outlets, We Keep Bulk Stock of Alloy Steel A182 F9 Insertweldolet at our stockyard, contact us to request a quote.

Alloy Steel A182 F9 Outlets Specifications

| AS F9 Outlet Fittings Standard | ASTM A182 / ASME SA182 |

|---|---|

| Alloy Steel F9 Outlet Fittings Dimensions | ASME / ANSI B16.11, MSS-SP-97, MSS-SP-79, JIS B2316, BS 3799 etc |

| F9 Alloy Steel Outlet Fittings Size | 1/8″-4″ (DN6-DN100) |

| F9 Alloy Steel Outlet Fittings Connect Type | Welded, threaded, BW, SW |

| F9 Alloy Steel Outlet Pipe Diameter | DN15 ~ DN40 |

| AS F9 Outlet Fittings | 2000 LBS, 3000 LBS, 6000 LBS, 9000 LBS |

| Alloy Steel F9 Outlet Process | Free forging, plate cutting, forged |

| Origin of F9 Alloy Steel Outlet | Indian Origin, European Origin, Japanese Origin |

| AS F9 Outlet Fittings Packing | Packed in Wooden Boxes, Bubble wraps, Steel Strips Bundled, or as per Customers Requests |

| Test Certificates |

Mill Test Certificates AS F9 Outlet Fittings Chemical Reports EN 10204 3.1 Mechanical Reports, Destructive Test Report Non Destructive Test Reports AS F9 Outlet Fittings PMI Test Reports F9 Alloy Steel Outlet Fittings Visual Inspection Reports NABL Approved Lab Reports |

| Material Test Certificates (MTC) as per EN 10204 3.1 and EN 10204 3.2 Test Certificates certifying NACE MR0103, NACE MR0175 | |