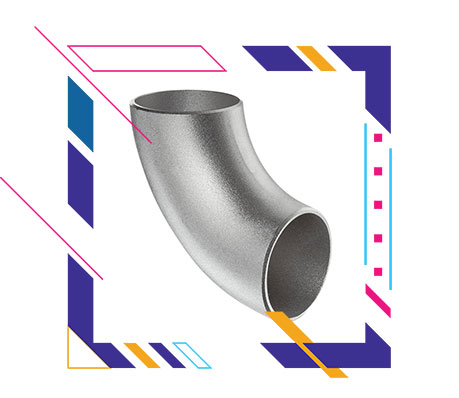

Ready Stock Of Super Duplex Steel S32760 Pipe Fittings, SDSS S32750 Elbow, Manufacturer of ASTM A403 SDSS S32750 Pipe Elbow, Super Duplex 2507 Buttweld Fittings, Super Duplex Grade S32760 LR Elbow Supplier in Mumbai.

Unifit Metal Alloys is a supplier of Super Duplex Steel Butt Weld Pipe Fittings, whichare offered at the most competitive prices to our valued customers.

If tempering in this range is required to achieve the appropriate strength and ductility values, it is possible that the decreased impact strength is not an issue and that the corrosion resistance is only minimally reduced in many instances. Super Duplex S32750 Cross Pipe Fittings have adequate resistance to nitric acid, strong sulphuric acid, weak acetic acid, and naphtha, and excellent resistance to food acids. Heat this steel evenly to 1100 Degree C – 1200 Degree C, then hold until the temperature is consistent throughout the portion. This steel, however, is susceptible to chloride assault, especially in oxidising circumstances.

ANSI B16.9 Super Duplex Stainless Steel S32760 Welded Fittings, SDSS S32760 Reducer, Super Duplex SAF 2507 90 Degree Elbow, S32760 Super Duplex Steel Pipe Fittings, SDSS DIN 1.4462 Stub End, Super Duplex Steel UNS S32750 Buttweld Fittings, Super Duplex Stainless Steel S32750 Short Radius Elbow, Super Duplex Grade S32750 Pipe Cap Manufacturer In Mumbai, India.

When adequate quantities of carbon are added to straight-chromium steels, this product has the ability to change its microstructure into one with optimal strength, hardness, edge retention, and wear resistance through proper heat treatment (hardening). This Super Duplex S32760 Stub End Pipe Fittings can also be used in mildly chlorinated and deserted water, where it should be heated to 1750°F / 1850 Degree F (955 Degree C / 1010 Degree C), soaked in oil, and allowed to settle naturally. They withstand ammonia, nitric acid, concentrated sulphuric acid, dilute acetic acid, and naphtha well, but post-weld thermal treatment should be considered to obtain the desired characteristics.

Tempering should be avoided at temperatures ranging from 425 Degree C to 600 Degree C due to the accompanying poor impact resistance. This is a hard enable, straight chromium steel that blends strong carbon alloy wear resistance with chromium steel corrosion resistance. This Super Duplex 2507 End Cap Pipe Fittings is made of martens tic steel, which has great strength and hardness as well as excellent corrosion protection.This steel is magnetic in both the annealed and hardened states, and various heat treatments can produce a broad variety of characteristics. Oil quenching these steels at temps ranging from 1800°F to 1950°F (982°C to 1066°C) results in the greatest strength, wear resistance, and rust resistance.

Get a best quote for SDSS S32750 Seamless Fittings, We Keep Bulk Stock of Super Duplex Stainless Steel S32760 Buttweld Pipe Fittings at our stockyard, contact us to request a quote.

Super Duplex Steel S32750 / S32760 Pipe Fittings Specifications

| Specifications | ASTM A403 / ASME SA403 |

|---|---|

| Dimensions | ASME/ANSI B16.9, ASME B16.28, MSS-SP-43, BS4504, BS4504, BS1560, BS10 ASME 16.11, MSS SP-79, 83, 95, 97, BS 3799 |

| Size | Seamless Fittings: 1/2" - 10" Welded Fittings: 1/2" - 48" |

| Thickness | SCH10, SCH20, SCH30, STD SCH40, SCH60, XS, SCH 80, SCH 100, SCH 120, SCH 140, SCH 160, XXS available with NACE MR 01-75 |

| Manufacturing Standards | ASME/ANSI B16.9, ASME B16.28, MSS-SP-43 DIN : DIN2605, DIN2615, DIN2616, DIN2617, DIN28011, DN15-DN1200 BS : BS4504, BS4504, BS1560, BS10 JIS : JIS B2311, JIS B2312, JIS B2313, JIS B2316 GOST : GOST 17375, GOST 17376, GOST 30753, GOST 17378, GOST 17379, GOST 17380 EN: EN10253-1, EN10253-2 |

| Types | Seamless / ERW / Welded / Fabricated |

| Connection | Welding |

| Bending Radius | R=1D, 2D, 3D, 5D, 6D, 8D, 10D or Custom |

| Elbow | Angle : 22.5 deg, 30deg, 45 deg, 90 deg, 180 deg, 1.0D, 1.5D, 2.0D, 2.5D, 3D, 4D, 5D, 6D, 7D-40D. Standard: ASME B16.9, ASME B16.28, ASME B16.25, MSS SP-75 DIN2605 JISB2311 JISB2312 JISB2313, BS, GB, ISO |

| Manufacturing process | Push, Press, Forge, Cast, etc. |

| Specialized manufacturer of | 90º Elbows, Couplings, Reducers, Inserts, Caps, Nipples, 45º Elbows, Tees, Crosses, Equal Tees & Reducing Tees |

| Test Certificates | EN 10204/3.1B Raw Materials Certificate 100% Radiography Test Report Third Party Inspection Report, etc |

| Material Test Certificates (MTC) as per EN 10204 3.1 and EN 10204 3.2, Test Certificates certifying NACE MR0103, NACE MR0175 | |