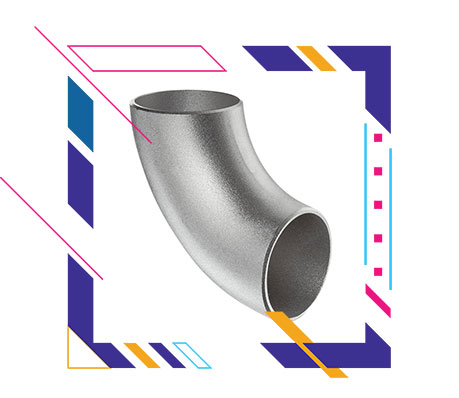

Ti Gr 5 LR Elbow, High Quality Titanium Gr 5 Buttweld Fittings, Ready Stock Of Ti Alloy Gr. 5 Pipe Fittings, Titanium Gr 5 Elbow, Manufacturer of ASTM B366 Titanium Alloy Grade 5 Pipe Elbow Supplier in Mumbai.

Unifit Metal Alloys is a supplier of Titanium Grade 5 Pipe Fittings, which can be welded utilizing the majority of traditional fusion and resistance processes.

We may use this Titanium UNS R56400 Cross Pipe Fittings to design and create tooling for the automotive, appliance, transportation, construction, agricultural, and lawn and garden industries, ranging from small line dies to extremely big transfer and progressive dies. It is utilized in a variety of industries including chemical, food processing, petrochemical, and pharmaceutical, power generation, pulp & paper, and so on. Corrosion in Crucial Crevices This product's temperature is the critical crevice corrosion temperature determined by laboratory studies. Also, the nitrogen in this steel contributes to the alloy's mechanical strength.

Ti Alloy Grade 5 Pipe Fittings, DIN 3.7165 Stub End, Titanium Alloy Grade 5 90 Degree Elbow, Ti Alloy Gr 5 Pipe Cap, UNS R56400 Buttweld Fittings, Grade 5 Titanium Reducer, Titanium Alloy Gr 5 Short Radius Elbow, ANSI B16.9 Ti Gr 5 Welded Fittings Manufacturer In Mumbai, India.

Titanium DIN 3.7165 Stub End Pipe Fittings can be cold rolled to achieve the temper qualities specified by consumers and/or manufacturers. It has great fabric ability and formability, which are typical of austenitic alloys, in addition to outstanding corrosion resistance and strength capabilities. It might be utilized in air pollution control equipment such as flue gas desulfurization systems, chemical and petrochemical processes, and the pulp and paper sector, for example. It has a high strength grade and is resistant to atmospheric corrosion, and its bright, appealing surface makes it a good choice for ornamental structural applications. It's widely employed in the aircraft and missile industries.

Pipe lengths of this Ti-6Al-4V End Cap Pipe Fittings are not precisely cut to length at the manufacturer, but are often provided as single random length and double random length. It contains qualities such as heat resistance, temperature resistance, a longer shelf life, and more. Aerospace - piston engine manifolds, Chemical Processing, Expansion Joints, and other applications are common. It is often used for components that are occasionally heated up to 1500 degrees Fahrenheit, but it is mostly utilized for continuous service where the alloy is good to 1650 degrees Fahrenheit. The titanium in this alloy provides several desirable properties, such as preventing hazardous carbide precipitation in the heat affected zone (HAZ) of the weld region.

Get a best quote for Titanium Gr 5 Seamless Fittings, We Keep Bulk Stock of Titanium Alloy Gr 5 Buttweld Pipe Fittings at our stockyard, contact us to request a quote.

Titanium Gr 5 Pipe Fittings Specifications

| Specifications | ASTM B366 / ASME SB366 |

|---|---|

| Dimensions | ASME/ANSI B16.9, ASME B16.28, MSS-SP-43, BS4504, BS4504, BS1560, BS10 ASME 16.11, MSS SP-79, 83, 95, 97, BS 3799 |

| Size | Seamless Fittings: 1/2" - 10" Welded Fittings: 1/2" - 48" |

| Thickness | SCH10, SCH20, SCH30, STD SCH40, SCH60, XS, SCH 80, SCH 100, SCH 120, SCH 140, SCH 160, XXS available with NACE MR 01-75 |

| Manufacturing Standards | ASME/ANSI B16.9, ASME B16.28, MSS-SP-43 DIN : DIN2605, DIN2615, DIN2616, DIN2617, DIN28011, DN15-DN1200 BS : BS4504, BS4504, BS1560, BS10 JIS : JIS B2311, JIS B2312, JIS B2313, JIS B2316 GOST : GOST 17375, GOST 17376, GOST 30753, GOST 17378, GOST 17379, GOST 17380 EN: EN10253-1, EN10253-2 |

| Types | Seamless / ERW / Welded / Fabricated |

| Connection | Welding |

| Bending Radius | R=1D, 2D, 3D, 5D, 6D, 8D, 10D or Custom |

| Elbow | Angle : 22.5 deg, 30deg, 45 deg, 90 deg, 180 deg, 1.0D, 1.5D, 2.0D, 2.5D, 3D, 4D, 5D, 6D, 7D-40D. Standard: ASME B16.9, ASME B16.28, ASME B16.25, MSS SP-75 DIN2605 JISB2311 JISB2312 JISB2313, BS, GB, ISO |

| Manufacturing process | Push, Press, Forge, Cast, etc. |

| Specialized manufacturer of | 90º Elbows, Couplings, Reducers, Inserts, Caps, Nipples, 45º Elbows, Tees, Crosses, Equal Tees & Reducing Tees |

| Test Certificates | EN 10204/3.1B Raw Materials Certificate 100% Radiography Test Report Third Party Inspection Report, etc |

| Material Test Certificates (MTC) as per EN 10204 3.1 and EN 10204 3.2, Test Certificates certifying NACE MR0103, NACE MR0175 | |