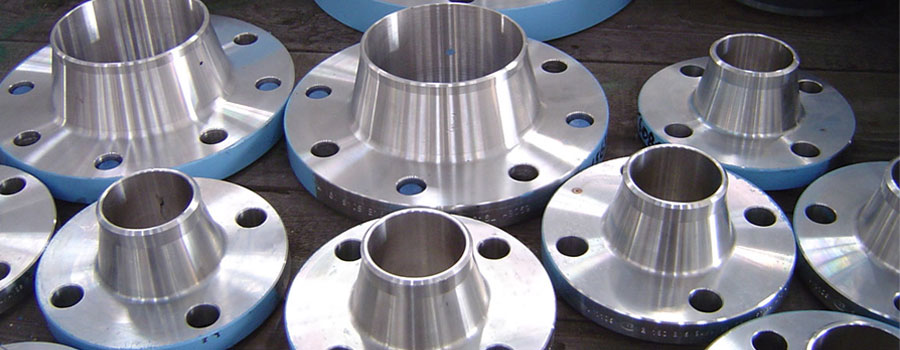

ANSI B16.5 Class 150 WNFF Flanges, Ready Stock Of Raised Faced Weld-Neck Flanges, Stainless Steel Weld Neck Flanges, EN1092-1 WNRF Flanges, Inconel WNRF Flange, Manufacturer of Flat Faced Weld Neck Flanges Supplier in Mumbai.

Unifit Metal Alloys is a distinguished supplier of Weld Neck Pipe Flanges, which can be welded using any conventional technique. Its appropriate heated work range is 2000 degrees Fahrenheit to 2200 degrees Fahrenheit (1093 degrees Celsius to 1204 degrees Celsius), but it should not be worked below 1650 degrees Fahrenheit (899 Degree C). Super Duplex Steel Weld Neck Flanges is hard enable steel that can be tempered as high as 1350 degrees Fahrenheit to create high impact toughness and is oxidation resistant up to 1500 degrees Fahrenheit sporadically and 1200 degrees Fahrenheit constantly. Temper for desired rigidity, furnace or air cool to 1750°F - 1850°F (954°C - 1010°C), and oil quench for maximum hardness. This steel is typically chosen based on heat treating reaction, mechanical qualities, and fabricating traits, depending on the customer's end-use needs.

Inconel Raised Face Weld Neck Flange, ANSI B16.5 WNRF Flanges, Nickel Alloy Weld Neck Plate Flanges, Alloy 20 WNRTJ Flanges, API 6A WNRF Flange, ASTM A182 SS Weld Neck Flange, Carbon Steel Weld Neck Flange, Flat Faced Weld Neck Flanges Manufacturer In Mumbai, India.

Reduce the annealing temperature to increase the toughness of this steel, while for optimum softness heat to 1500° F / 1650° F (815° C / 900° C) and slowly chill the kiln. Stainless Steel Weld Neck Flanges has good hardness characteristics after heat treatment and is appropriate for use in stressed components. It is not suggested in the hardened and tempered as provided state due to its impact on the mechanical properties within the heat affected zone. It is used in a variety of applications such as press plates, petrochemical equipment, firearms manufacturing, gate valves, mining gear, distillation trays, and so on.

Thin sheet portions of this lower chromium martens tic steel should not be preheated to 550 degrees Fahrenheit (260 degrees Celsius). Carbon Steel Weld Neck Flanges can be used in settings with mild or diluted acetic acid, naphtha, nitric acid, and sulphuric acid, and they are also immune to acids found in foods. The working temperatures of this steel are commonly impacted by its loss of potency at soaring temperatures owing to over-tempering and loss of ductility at low temperatures. By changing the carbon amount, these products can attain a variety of as-quenched hardness. This product is easily forged, headed, or upset, necessitating more strikes or a stronger mallet than mild steel.

Get a best quote for SS WNRF Flanges, We Keep Bulk Stock of Raised Face Weld Neck Flanges at our stockyard, contact us to request a quote.

Weld Neck Flanges Specifications

| Size Chart | 1/2" (15 NB) to 48" (1200NB) DN10~DN5000 |

|---|---|

| Standards | ANSI/ASME B16.5, B16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, ASME Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, GOST Flange, ASME/ASME B16.5/16.36/16.47A/16.47B, MSS S44, ISO70051, JISB2220, BS1560-3.1, API7S-15, API7S-43, API605, EN1092 |

| Pressure Rating ANSI | Class 150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS |

| DIN | 6Bar 10Bar 16Bar 25Bar 40Bar / PN6 PN10 PN16 PN25 PN40, PN64 |

| JIS | 5K, 10 K, 16 K 20 K, 30 K, 40 K, 63 K |

| UNI | 6Bar 10Bar 16Bar 25Bar 40Bar |

| EN | 6Bar 10Bar 16Bar 25Bar 40Bar |

| Coating | Oil Black Paint, Anti-rust Paint, Zinc Plated, Yellow Transparent, Cold and Hot Dip Galvanized |

| Most Common Types | Forged / Threaded / Screwed / Plate |

| Test Certificates | EN 10204/3.1B Raw Materials Certificate 100% Radiography Test Report Third Party Inspection Report, etc |

| Production technique |

|

| Connect Type/ Flange Face Type | Raised Face (RF), Ring Type Joint (RTJ), Flat Face (FF), Large Male-Female (LMF), Lap-Joint Face (LJF), Small Male-Female (SMF), Small Tongue, Large Tongue & Groove |

| Special design | As per your drawing |

| Test | Direct-reading Spectrograph, Hydrostatic testing machine, X-ray detector, UI trasonic flaw detector, Magnetic particle detector |

| Equipment | Press machine, Bending machine, Pushing Machine, electric bevelling machine, Sand-blasting machine etc |

| Origin | Indian / West Europe / Japan / USA / Korean |

| Manufacturer of | ASME DIN, GOST, JIS, UNI, BS, AS2129, AWWA, EN, SABS, NFE etc.

|

| Uses & Application |

|