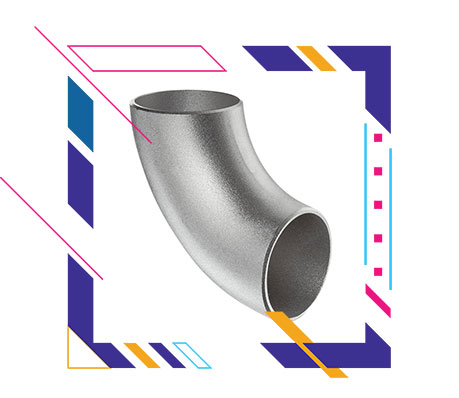

Alloy Steel A234 WP5 Elbow, Ready Stock Of Gr WP5 Alloy Steel Pipe Fittings, Manufacturer of ASTM A234 CrMo WP5 Pipe Elbow, WP5 CrMo LR Elbow, WP5 Alloy Steel Buttweld Fittings Supplier in Mumbai.

Unifit Metal Alloys is an acknowledged trader and exporter of AS A234 WP5 Pipe Fittings, which is offered in a variety of finishes to meet the needs of various sectors.

Alloy Steel ASTM A234 WP5 5D Elbow Pipe Fittings, which is used in the pipe fitting uses of oil, chemical, gas, petrochemical, and food manufacturing units, is of high quality. Clients can buy the provided products from us in various sizes and other associated stipulations based on their requirements. It has several unique properties, including a rust-free smooth surface, a lengthy working life, and a high tensile strength. They are made at our facility from high-quality steel. And so has good mechanical properties, a high temperature chemical procedure, and a high temperature steam operation.

Alloy Steel A234 WP5 Short Radius Elbow, WP5 Alloy Steel Reducer, CrMo WP5 Buttweld Fittings, Cr-Mo A234 WP5 Stub End, Gr WP5 Alloy Steel Pipe Fittings, Alloy Steel WP5 90 Degree Elbow, WP5 Alloy Steel Pipe Cap, ANSI B16.9 WP5 CrMo Welded Fittings Manufacturer In Mumbai, India.

We are a leading supplier of this ASTM A234 Alloy Steel WP5 Butt Weld Tee Pipe Fittings, which is produced using sophisticated technology and high-quality steel. It has characteristics such as Excellent finish, Robust build, Exquisite quality, and others. They are accessible in a variety of sizes and shapes that customers can buy based on their needs. Our quality section carefully inspects them to ensure that they are defect-free. They are made from high-quality components and adhere to world-class standards. It is widely used in a variety of sectors and provides an unrestricted flow of liquid that can be controlled as needed. They are aided by the introduction of nuts that can be tightly grasped while preventing loose working.

ASME SA 234 Alloy Steel WP5 Pipe Fittings are made with high-quality materials to prevent abrasion and rusting of the pipe. In addition, they are tested on numerous quality criteria to ensure flawlessness before being released to the market. We deliver these products to clients on a variety of specifications on time. They are extensively used in building, industrial engineering, power generation, and a variety of other sectors. It has characteristics such as high conductive value, accurate dimensions, improved heat transmission, maximum strength, non-corrosive, scratch-free, vibration-absorbing, sturdy construction, and dimensional precision, among others. They are made with high-quality components and meet worldwide quality requirements.

Get a best quote for Alloy Steel A234 WP5 Seamless Fittings, We Keep Bulk Stock of Cr-Mo A234 WP5 Buttweld Pipe Fittings at our stockyard, contact us to request a quote.

Alloy Steel A234 WP5 Pipe Fittings Specifications

| Specifications | ASTM A234 / ASME SA234 |

|---|---|

| Dimensions | ASME/ANSI B16.9, ASME B16.28, MSS-SP-43, BS4504, BS4504, BS1560, BS10 ASME 16.11, MSS SP-79, 83, 95, 97, BS 3799 |

| Size | Seamless Fittings: 1/2" - 10" Welded Fittings: 1/2" - 48" |

| Thickness | SCH10, SCH20, SCH30, STD SCH40, SCH60, XS, SCH 80, SCH 100, SCH 120, SCH 140, SCH 160, XXS available with NACE MR 01-75 |

| Manufacturing Standards | ASME/ANSI B16.9, ASME B16.28, MSS-SP-43 DIN : DIN2605, DIN2615, DIN2616, DIN2617, DIN28011, DN15-DN1200 BS : BS4504, BS4504, BS1560, BS10 JIS : JIS B2311, JIS B2312, JIS B2313, JIS B2316 GOST : GOST 17375, GOST 17376, GOST 30753, GOST 17378, GOST 17379, GOST 17380 EN: EN10253-1, EN10253-2 |

| Types | Seamless / ERW / Welded / Fabricated |

| Connection | Welding |

| Bending Radius | R=1D, 2D, 3D, 5D, 6D, 8D, 10D or Custom |

| Elbow | Angle : 22.5 deg, 30deg, 45 deg, 90 deg, 180 deg, 1.0D, 1.5D, 2.0D, 2.5D, 3D, 4D, 5D, 6D, 7D-40D. Standard: ASME B16.9, ASME B16.28, ASME B16.25, MSS SP-75 DIN2605 JISB2311 JISB2312 JISB2313, BS, GB, ISO |

| Manufacturing process | Push, Press, Forge, Cast, etc. |

| Specialized manufacturer of | 90º Elbows, Couplings, Reducers, Inserts, Caps, Nipples, 45º Elbows, Tees, Crosses, Equal Tees & Reducing Tees |

| Test Certificates | EN 10204/3.1B Raw Materials Certificate 100% Radiography Test Report Third Party Inspection Report, etc |

| Material Test Certificates (MTC) as per EN 10204 3.1 and EN 10204 3.2, Test Certificates certifying NACE MR0103, NACE MR0175 | |