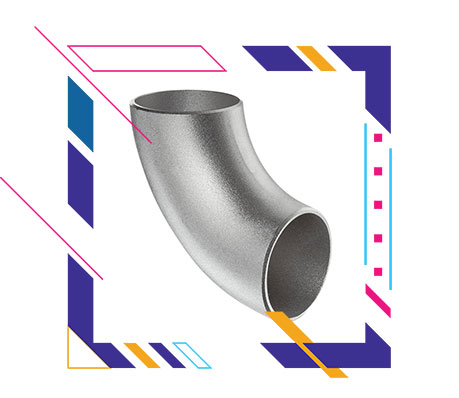

Inconel 600 Elbow, Ready Stock Of Alloy 600 Pipe Fittings, Manufacturer of ASTM B366 Inconel Alloy 600 Pipe Elbow, 600 Inconel LR Elbow, Nickel Alloyl 600 Buttweld Fittings Supplier in Mumbai.

Unifit Metal Alloys is supplier and manufacturer of Inconel Alloy 600 Pipe Fittings, which performs better at high temperatures. This steel's resistance to corrosive environments is not limited to reducing elements, though this is where it excels, as Inconel UNS N06600 Cross Pipe Fittings also performs well in some oxidising conditions. It is resistant to all dry gases at room temperature and can be used in dry chlorine and hydrogen chloride at temperatures up to 550 degrees Celsius. Because of the addition of columbium, this steel has excellent corrosion resistance, even better than alloy steel. For the reason that the required standard will be fully met as specified on the order, the chemical composition of this alloy may vary slightly between different product standards.

Nickel Alloy 600 Short Radius Elbow, Inconel® Alloy 600 Reducer, UNS N06600 Buttweld Fittings, DIN 2.4816 Stub End, 600 Inconel Pipe Fittings, Grade 600 Inconel 90 Degree Elbow, Alloy 600 Pipe Cap, ANSI B16.9 Inconel 600 Welded Fittings Manufacturer In Mumbai, India.

We are the leading manufacturers of this Inconel WNR 2.4816 Stub End Pipe Fittings, with various sizes available depending on the length required. It is typically used for parts that are intermittently heated up to 1500 degrees Fahrenheit, with a maximum temperature of 1650 degrees Fahrenheit for continuous service. Cold reduction is the only way to take advantage of the alloy's superior properties in this steel. It has the same general corrosion resistance as unsterilized chromium nickel alloy. The addition of columbium and tantalum in this alloy provides some desired properties. It is primarily used where corrosion resistance and long-term operation at temperatures ranging from 800 to 1600 degrees Fahrenheit are critical.

Nickel Alloy 600 End Cap Pipe Fittings, which are used in a petrochemical plant, must have acceptable hot corrosion resistance, creep resistance, and fatigue resistance. It is electrically and thermally conductive. It is extremely resistant to reducing chemicals and has an unrivalled resistance to caustic alkalis. Because the oxide film accounts for the material's excellent resistance in caustic environments, all hot and cold working techniques can be used when shaping this steel. It has good corrosion resistance and is frequently used to handle caustic soda, where it forms an oxide film that protects it. It works best in reducing environments, but it can also be used in oxidising environments to form a passive oxide layer.

Get a best quote for Inconel 600 Seamless Fittings, We Keep Bulk Stock of Inconel Alloy 600 Buttweld Pipe Fittings at our stockyard, contact us to request a quote.

Inconel Alloy 600 Pipe Fittings Specifications

| Specifications | ASTM B366 / ASME SB366 |

|---|---|

| Dimensions | ASME/ANSI B16.9, ASME B16.28, MSS-SP-43, BS4504, BS4504, BS1560, BS10 ASME 16.11, MSS SP-79, 83, 95, 97, BS 3799 |

| Size | Seamless Fittings: 1/2" - 10" Welded Fittings: 1/2" - 48" |

| Thickness | SCH10, SCH20, SCH30, STD SCH40, SCH60, XS, SCH 80, SCH 100, SCH 120, SCH 140, SCH 160, XXS available with NACE MR 01-75 |

| Manufacturing Standards | ASME/ANSI B16.9, ASME B16.28, MSS-SP-43 DIN : DIN2605, DIN2615, DIN2616, DIN2617, DIN28011, DN15-DN1200 BS : BS4504, BS4504, BS1560, BS10 JIS : JIS B2311, JIS B2312, JIS B2313, JIS B2316 GOST : GOST 17375, GOST 17376, GOST 30753, GOST 17378, GOST 17379, GOST 17380 EN: EN10253-1, EN10253-2 |

| Types | Seamless / ERW / Welded / Fabricated |

| Connection | Welding |

| Bending Radius | R=1D, 2D, 3D, 5D, 6D, 8D, 10D or Custom |

| Elbow | Angle : 22.5 deg, 30deg, 45 deg, 90 deg, 180 deg, 1.0D, 1.5D, 2.0D, 2.5D, 3D, 4D, 5D, 6D, 7D-40D. Standard: ASME B16.9, ASME B16.28, ASME B16.25, MSS SP-75 DIN2605 JISB2311 JISB2312 JISB2313, BS, GB, ISO |

| Manufacturing process | Push, Press, Forge, Cast, etc. |

| Specialized manufacturer of | 90º Elbows, Couplings, Reducers, Inserts, Caps, Nipples, 45º Elbows, Tees, Crosses, Equal Tees & Reducing Tees |

| Test Certificates | EN 10204/3.1B Raw Materials Certificate 100% Radiography Test Report Third Party Inspection Report, etc |

| Material Test Certificates (MTC) as per EN 10204 3.1 and EN 10204 3.2, Test Certificates certifying NACE MR0103, NACE MR0175 | |