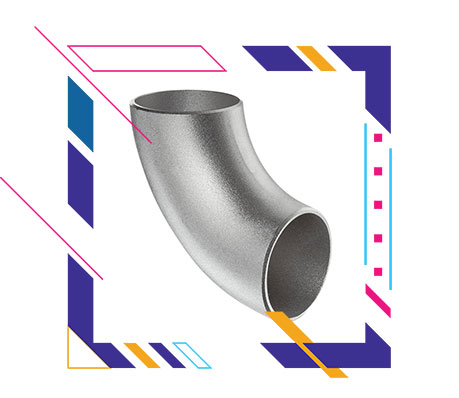

Nickel Alloyl 625 Buttweld Fittings, Inconel 625 Elbow, Manufacturer of ASTM B366 Inconel Alloy 625 Pipe Elbow, 625 Inconel LR Elbow, Ready Stock Of Alloy 625 Pipe Fittings Supplier in Mumbai.

Unifit Metal Alloys is supplier of Inconel Alloy 625 Pipe Fittings, whichis an alloyed molybdenum bearing austenitic chromium nickel steel. Inconel UNS N06625 2D Elbow Pipe Fittings is tougher than other steels with a long stringy chip, so chip breakers are recommended in this alloy. Because of the benefits and chemical composition of this product, it is widely used in a variety of industries for a wide range of applications. This steel should be annealed at temperatures ranging from 1010 to 1121 degrees Celsius (1850 to 2050 degrees Fahrenheit), followed by rapid cooling. They are resistant to concentrations of this acid at temperatures as high as 120 degrees Fahrenheit (49 degrees Celsius). Shielded fusion and resistance methods can be used to weld it, but oxyacetylene welding should be avoided to avoid carbon pick up in the welds.

DIN 2.4856 Stub End, 625 Inconel Pipe Fittings, UNS N06625 Buttweld Fittings, Nickel Alloy 625 Short Radius Elbow, Inconel® Alloy 625 Reducer, Alloy 625 Pipe Cap, ANSI B16.9 Inconel 625 Welded Fittings, Grade 625 Inconel 90 Degree Elbow Manufacturer In Mumbai, India.

Corrosion-resistant boiler parts include rollers, conveyor belts, burner parts, retorts and oven linings, refractory supports, fans, tube hangers, and trays and baskets to hold small parts. Inconel WNR 2.4856 3D Elbow Pipe Fittings are appropriate for vertical organisations such as boiler units, power plants, heat exchanger units, oil and gas exploration, and so on. Heat treatment has no effect on it. Except for oxyacetylene welding, all typical fusion and resistance procedures for this steel have been effective. It's utilised in paper and pulp equipment, chemical and petrochemical processing, food processing, power generation (both fossil and nuclear), flue gas desulfurization systems, and other applications.

They have great tolerance to larger concentrations at temperatures below 100 degrees Fahrenheit (38 degrees Celsius). Nickel Alloy 625 5D Elbow Pipe Fittings is also used in the chemical process sector to hold hot concentrated acids, ammonia, and sulphur dioxide, as well as in the food processing business, where it comes into touch with hot acetic and citric acid. It offers excellent corrosion resistance in harsh situations. They are also utilised in the construction sector, chemical and fertiliser manufacturing, engineering and shipbuilding, onshore and offshore industries, Chillers and cooling systems, surgical instruments, fasteners, and so on.

Get a best quote for Inconel 625 Seamless Fittings, We Keep Bulk Stock of Inconel Alloy 625 Buttweld Pipe Fittings at our stockyard, contact us to request a quote.

Inconel Alloy 625 Pipe Fittings Specifications

| Specifications | ASTM B366 / ASME SB366 |

|---|---|

| Dimensions | ASME/ANSI B16.9, ASME B16.28, MSS-SP-43, BS4504, BS4504, BS1560, BS10 ASME 16.11, MSS SP-79, 83, 95, 97, BS 3799 |

| Size | Seamless Fittings: 1/2" - 10" Welded Fittings: 1/2" - 48" |

| Thickness | SCH10, SCH20, SCH30, STD SCH40, SCH60, XS, SCH 80, SCH 100, SCH 120, SCH 140, SCH 160, XXS available with NACE MR 01-75 |

| Manufacturing Standards | ASME/ANSI B16.9, ASME B16.28, MSS-SP-43 DIN : DIN2605, DIN2615, DIN2616, DIN2617, DIN28011, DN15-DN1200 BS : BS4504, BS4504, BS1560, BS10 JIS : JIS B2311, JIS B2312, JIS B2313, JIS B2316 GOST : GOST 17375, GOST 17376, GOST 30753, GOST 17378, GOST 17379, GOST 17380 EN: EN10253-1, EN10253-2 |

| Types | Seamless / ERW / Welded / Fabricated |

| Connection | Welding |

| Bending Radius | R=1D, 2D, 3D, 5D, 6D, 8D, 10D or Custom |

| Elbow | Angle : 22.5 deg, 30deg, 45 deg, 90 deg, 180 deg, 1.0D, 1.5D, 2.0D, 2.5D, 3D, 4D, 5D, 6D, 7D-40D. Standard: ASME B16.9, ASME B16.28, ASME B16.25, MSS SP-75 DIN2605 JISB2311 JISB2312 JISB2313, BS, GB, ISO |

| Manufacturing process | Push, Press, Forge, Cast, etc. |

| Specialized manufacturer of | 90º Elbows, Couplings, Reducers, Inserts, Caps, Nipples, 45º Elbows, Tees, Crosses, Equal Tees & Reducing Tees |

| Test Certificates | EN 10204/3.1B Raw Materials Certificate 100% Radiography Test Report Third Party Inspection Report, etc |

| Material Test Certificates (MTC) as per EN 10204 3.1 and EN 10204 3.2, Test Certificates certifying NACE MR0103, NACE MR0175 | |