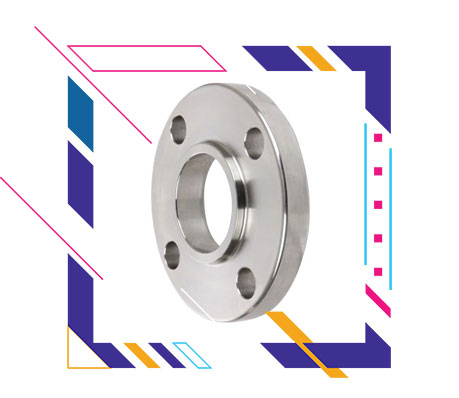

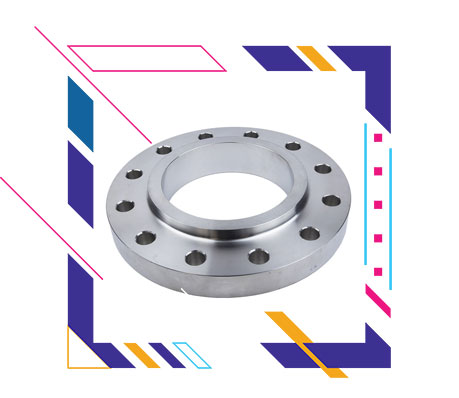

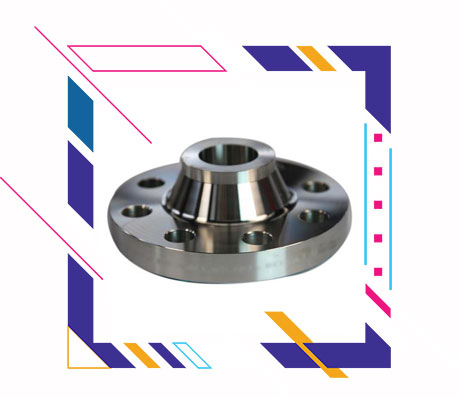

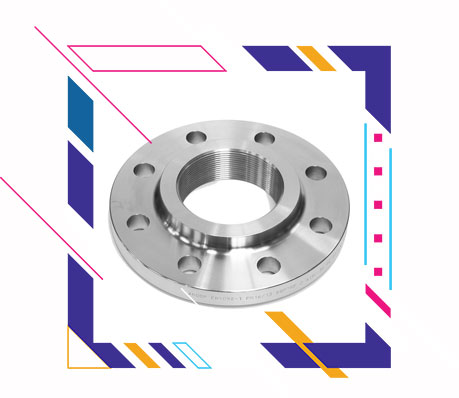

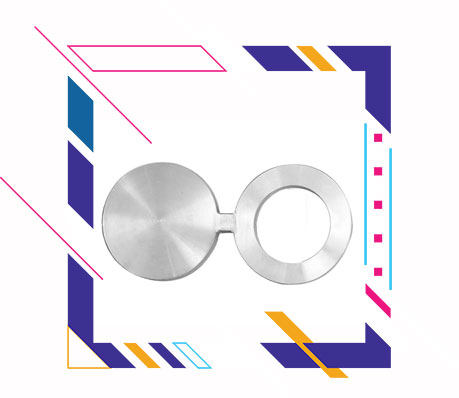

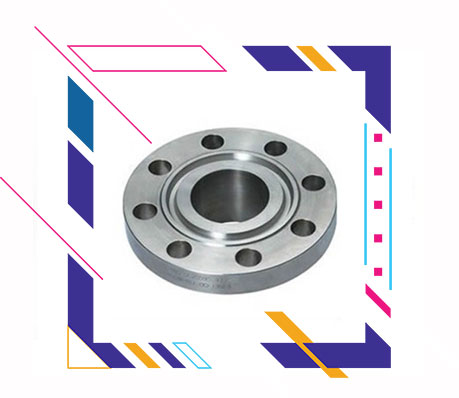

Manufacturer of ASTM A182 F317 Lap Joint Flanges, SS 317L Threaded Flanges, Stainless Steel 317 SORF Flanges, Ready Stock Of SS 317 Flanges, 317L SS Long Weld Neck Flanges Supplier in Mumbai.

Unifit Metal Alloys is a recognised manufacturer and trader of SS 317 / 317L Flanges, whichare commonly utilized when selecting a stainless steel that must withstand corrosive conditions. Stainless Steel UNS S31700 Lap Joint Flanges is very resistant to corrosion caused by dry chlorine and hydrogen chloride gas. The product's controlled chemical composition restrictions are used in the nuclear industry to avoid the possibility of stress corrosion cracking caused by high purity water containing chloride ions. Stainless Steel WNR1.4449 Puddle Flanges is resistant to water corrosion and has a high mechanical strength. This alloy's composition is a face-centered-cubic solid solution with exceptional metallurgical stability. It forms a firmly adhering oxide scale that withstands even extreme heat cycling. The existence of this alloy may create some misunderstanding, especially as the names and formulae are almost identical.

Manufacturer of ASTM A182 F317 Lap Joint Flanges, Ready Stock Of SS 317L Flanges, SS 317 Threaded Flanges, Stainless Steel 317 SORF Flanges, 317L SS Long Weld Neck Flanges Manufacturer In Mumbai, India.

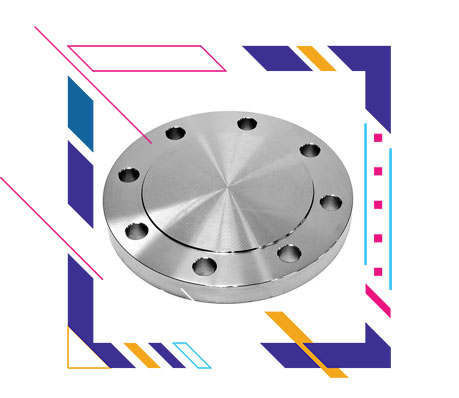

The product's nickel basis, along with a high chromium component, makes 317 Stainless Steel Spade Blind Flanges resistant to a wide range of corrosive media and high-temperature conditions. Under oxidizing circumstances, it has high hot corrosion resistance. It is often used in industrial furnaces and heat-treating equipment. Its primary non-iron components are chromium and nickel metals. Stainless Steel UNS S31703 Spacer Flanges is the standard steel and is regarded as the most versatile and widely used steel. It is the common stainless steel that you will most likely find in your pans and cooking equipment. It is a cost-effective and adaptable corrosion-resistant alloy that may be used in a variety of general-purpose applications.

Get a best quote for SS F317 SORF Flanges, We Keep Bulk Stock of Stainless Steel 317L Flanges at our stockyard, contact us to request a quote.

Stainless Steel 317/317L Flanges Specifications

| Size Chart | 1/2" (15 NB) to 48" (1200NB) DN10~DN5000 |

|---|---|

| Standards | ANSI/ASME B16.5, B16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, GOST Flange, ASME/ANSI B16.5/16.36/16.47A/16.47B, MSS S44, ISO70051, JISB2220, BS1560-3.1, API7S-15, API7S-43, API605, EN1092 |

| Pressure Rating | Class 150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS |

| Pressure Calculation in DIN | 6Bar 10Bar 16Bar 25Bar 40Bar / PN6 PN10 PN16 PN25 PN40, PN64 |

| UNI | 6Bar 10Bar 16Bar 25Bar 40Bar |

| EN | 6Bar 10Bar 16Bar 25Bar 40Bar |

| Coating | Oil Black Paint, Anti-rust Paint, Zinc Plated, Yellow Transparent, Cold and Hot Dip Galvanized |

| Most common types | Forged / Threaded / Screwed / Plate |

| Test Certificates | EN 10204/3.1B Raw Materials Certificate 100% Radiography Test Report Third Party Inspection Report, etc |

| Production Technique | Forged, Heat treated and machined |

| Connect Type/ Flange Face Type | Raised Face (RF), Ring Type Joint (RTJ), Flat Face (FF), Large Male-Female (LMF), Lap-Joint Face (LJF), Small Male-Female (SMF), Small Tongue, Large Tongue & Groove, Groove |

| Special design | As per your drawing AS, ANSI, BS, DIN and JIS |

| Test | Direct-reading Spectrograph, Hydrostatic testing machine, X-ray detector, UI trasonic flaw detector, Magnetic particle detector |

| Equipment | Press machine, Bending machine, Pushing Machine, electric bevelling machine, Sand-blasting machine etc |

| Manufacturer of | ANSI DIN, GOST, JIS, UNI, BS, AS2129, AWWA, EN, SABS, NFE etc. B.S: BS4504 , BS3293, BS1560, BS10 The other standard: AWWA C207; EN1092-1, GOST12820, JIS B2220; KS B1503, SABS1123; NFE29203; UNI2276 |