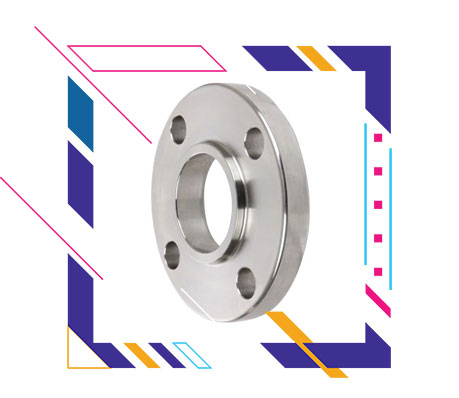

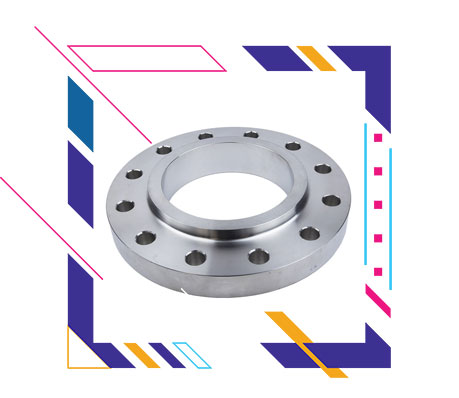

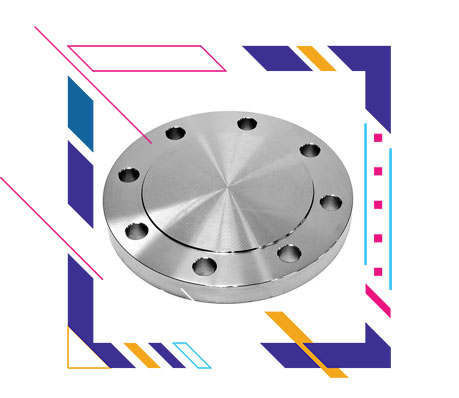

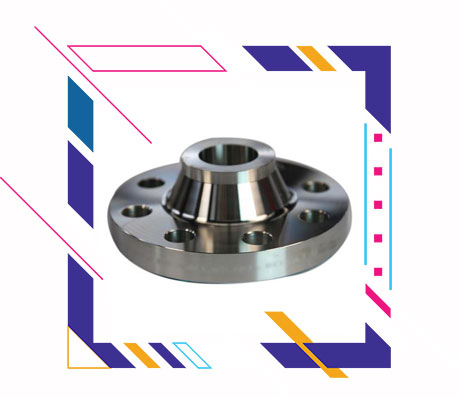

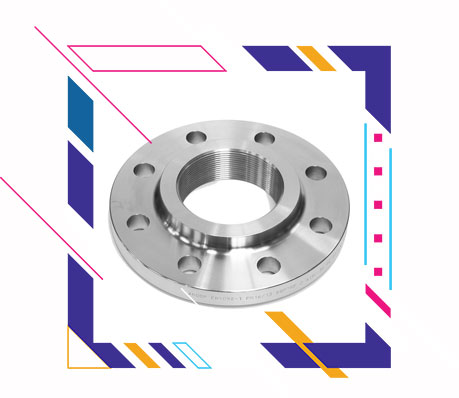

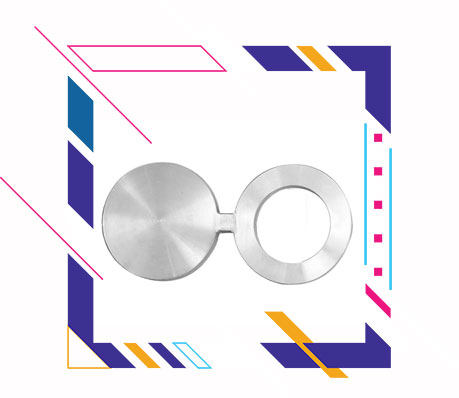

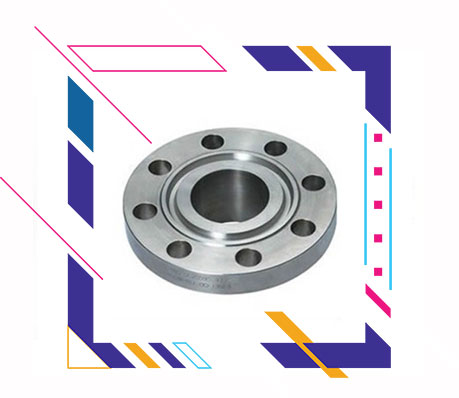

Ready Stock Of SS 347 Flanges, 347H SS Long Weld Neck Flanges, Manufacturer of ASTM A182 F347 Lap Joint Flanges, SS 347H Threaded Flanges, Stainless Steel 347 SORF Flanges Supplier in Mumbai.

Unifit Metal Alloys is a recognised manufacturer and seller of SS 347 / 347H Flanges, whichare long-lasting, corrosion-resistant, and an excellent choice for high-stress applications. Manganese, silicon, and carbon are other important alloying elements in this Stainless Steel UNS S34700 Spectacle Flanges, with iron accounting for the majority of the remaining chemical makeup. It significantly improves corrosion resistance, particularly in more salty or chloride-exposed situations. When in fact welding narrow kind of pieces, then no type of post-weld hardening is required. Stainless Steel WNR 1.4550 Long Weld Neck Flanges are frequently seen in industrial machinery (for example, in paper mills, chemical plants, water treatment). They are also utilized in chemical and food storage tanks and tankers (for example, chemical tankers and road tankers). They are also employed in food preparation equipment, particularly in chloride-containing conditions.

Ready Stock Of SS 347H Flanges, SS 347 Threaded Flanges, Manufacturer of ASTM A182 F347 Lap Joint Flanges, Stainless Steel 347 SORF Flanges, 347H SS Long Weld Neck Flanges Manufacturer In Mumbai, India.

347 Stainless Steel Lap Joint Flanges should be heated to 1149°C - 1260°C; nevertheless, it should not be heated below 927°C. Its resistance increases as the molybdenum alloy percentage increases.Increased chromium, nickel, and molybdenum levels in this steel improve chloride pitting resistance and overall corrosion resistance. At temperatures as high as 49 degrees Celsius, Stainless Steel UNS S34709 Puddle Flangesis resistant to sulfuric acid concentrations of up to 5%. It provides high resilience in situations where contamination must be kept to a minimal. It offers superior resistance in highly corrosive conditions containing sulphurous media, chlorides, and other halides.

Stainless Steel WNR 1.4961 Spade Blind Flanges is often utilized in the chemical and maritime sectors. This steel can be post-work annealed to maintain its corrosion resistance. It is utilized in oil and petroleum refining equipment, food processing equipment, pulp and paper processing equipment, and other similar applications. With this alloy, post-work annealing is advised for maximum corrosion resistance. Because of the low carbon concentration in this alloy, 347H Stainless Steel Spacer Flanges may be fused without inter-granular erosion, which results in chromium carbide precipitation, allowing it to be used in the as-soldered condition. It is resistant to low temperatures. It has a stronger affinity for carbon than columbium-tantalum and chromium, and carbides precipitate in the range of grains rather than at grain borders.

Get a best quote for SS F347 SORF Flanges, We Keep Bulk Stock of Stainless Steel 347H Flanges at our stockyard, contact us to request a quote.

Stainless Steel 347/347H Flanges Specifications

| Size Chart | 1/2" (15 NB) to 48" (1200NB) DN10~DN5000 |

|---|---|

| Standards | ANSI/ASME B16.5, B16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, GOST Flange, ASME/ANSI B16.5/16.36/16.47A/16.47B, MSS S44, ISO70051, JISB2220, BS1560-3.1, API7S-15, API7S-43, API605, EN1092 |

| Pressure Rating | Class 150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS |

| Pressure Calculation in DIN | 6Bar 10Bar 16Bar 25Bar 40Bar / PN6 PN10 PN16 PN25 PN40, PN64 |

| UNI | 6Bar 10Bar 16Bar 25Bar 40Bar |

| EN | 6Bar 10Bar 16Bar 25Bar 40Bar |

| Coating | Oil Black Paint, Anti-rust Paint, Zinc Plated, Yellow Transparent, Cold and Hot Dip Galvanized |

| Most common types | Forged / Threaded / Screwed / Plate |

| Test Certificates | EN 10204/3.1B Raw Materials Certificate 100% Radiography Test Report Third Party Inspection Report, etc |

| Production Technique | Forged, Heat treated and machined |

| Connect Type/ Flange Face Type | Raised Face (RF), Ring Type Joint (RTJ), Flat Face (FF), Large Male-Female (LMF), Lap-Joint Face (LJF), Small Male-Female (SMF), Small Tongue, Large Tongue & Groove, Groove |

| Special design | As per your drawing AS, ANSI, BS, DIN and JIS |

| Test | Direct-reading Spectrograph, Hydrostatic testing machine, X-ray detector, UI trasonic flaw detector, Magnetic particle detector |

| Equipment | Press machine, Bending machine, Pushing Machine, electric bevelling machine, Sand-blasting machine etc |

| Manufacturer of | ANSI DIN, GOST, JIS, UNI, BS, AS2129, AWWA, EN, SABS, NFE etc. B.S: BS4504 , BS3293, BS1560, BS10 The other standard: AWWA C207; EN1092-1, GOST12820, JIS B2220; KS B1503, SABS1123; NFE29203; UNI2276 |